For all your security requirements

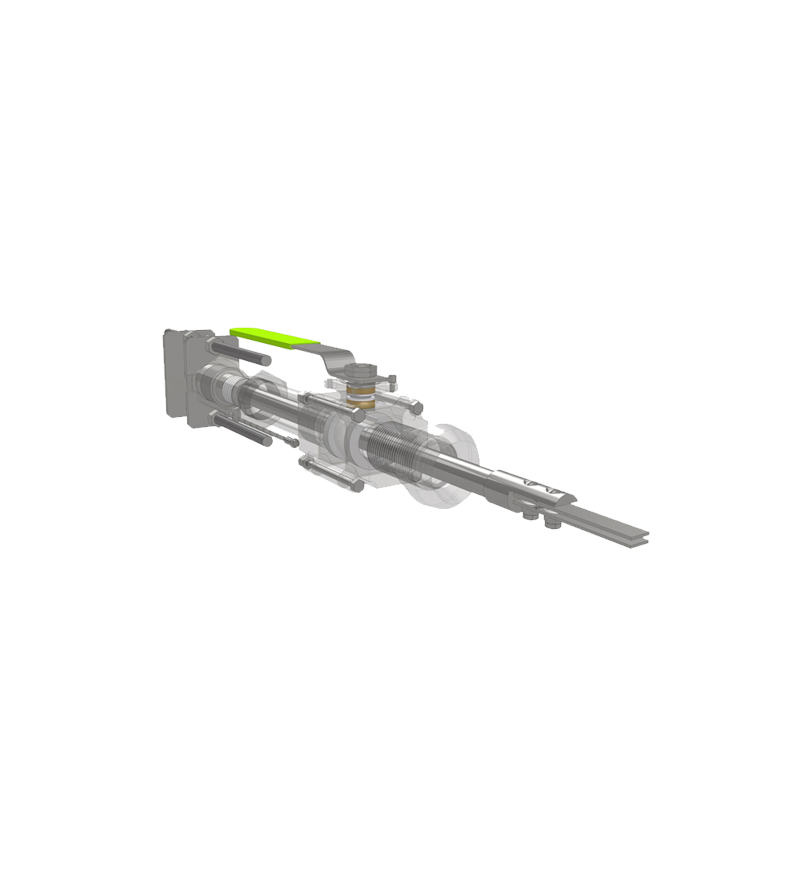

High pressure hydraulic access system

The hydraulic access and recovery device provides an integral, safe and reliable solution for in-line installation of probes and coupons in high pressure pipes and vessels, withstanding pressures up to 414 bar and temperatures up to 204°C.

High Pressure Mechanical Access Fitting System

The hydraulic access and recovery device provides an integral, safe and reliable solution for in-line installation of probes and coupons in high pressure pipes and vessels, withstanding pressures up to 414 bar and temperatures up to 204°C.

High Pressure Recovery Equipment

Corrosion recovery tools and service valves are used to efficiently and safely insert and recover probes, coupons, sensors and chemical injection devices from a process under operating conditions and pressures normal.

Retractable access system for low pressures

The Retractable Access System provides a complete solution for the safe and reliable in-line installation of coupons, probes, chemical injection and sampling devices on pipes and vessels at pressures up to 103 Bar and temperatures up to 260°C

AXHP Coupon Holder

Designed to be compatible with AXHP systems, these devices facilitate the insertion and removal of corrosion coupons in pressurized piping systems up to 689 bar.

Porte-coupons AXLP

Designed to facilitate the insertion and removal of corrosion coupons in piping systems pressurized up to 103 bar, this equipment is connected to a permanently attached full orifice valve.

Data collection unit

This high-resolution, battery-operated corrosion monitoring instrument is compatible with all types of electrical resistance (ER), linear polarization resistance (LPR) and galvanic probes.

High resolution wired transmitter

This online corrosion monitoring instrument is versatile and offers high resolution. With its high-resolution 20-bit measurement, it provides rapid results, allowing corrosion rates to be obtained in hours instead of days.

Wireless and remote monitoring

This wide selection of wireless and remote monitoring solutions incorporates a variety of intrusive probes such as electrical resistance (ER), linear polarization resistance (LPR), and galvanic probes, as well as non-intrusive thickness controllers. of the pipe wall by ultrasound.

Corrosion and electrical resistance erosion (ER) probes

Rapidly identifying corrosion trends is a fundamental aspect of establishing and improving an effective corrosion control program.

Linear Polarization Resistance (LPR) Probes

The LPR method makes it possible to determine the corrosion rate between the anodic and cathodic half-cells when the connection medium (the solution) is conductive.

Sand erosion probe

The Sand Erosion Probe is specifically developed to monitor erosion present in flow lines.

Hydrogen probes

In acidic environments, hydrogen atoms are often generated and can penetrate through steels, subsequently releasing as hydrogen molecules.

Non-intrusive high temperature control

Non-intrusive high temperature wall thickness measurement solutions are offered to monitor corrosion and erosion in service.

Coupon Bio-Film

Variety of bioprobes designed to monitor microbiologically influenced corrosion (MIC) in high and low pressure systems.

Corrosion coupons and electrodes

Metal test piece for corrosion determination.